Company

We have been setting standards for decades

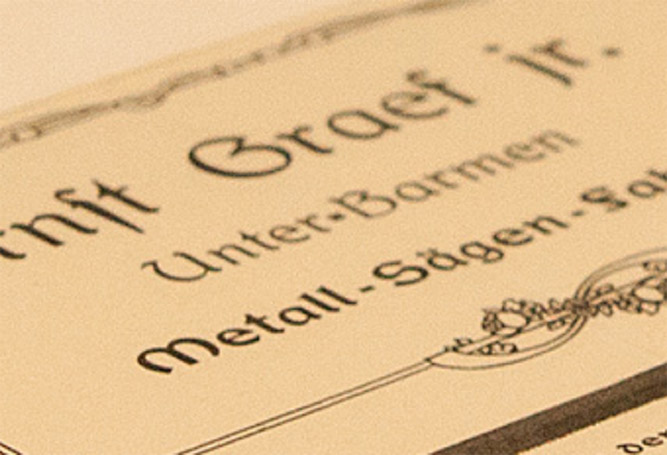

The plans for the foundation of a saw factory were initiated more than 118 years ago by Mr. Ernst Graef jr. in a small house on the outskirts of the town of Barmen (today’s Wuppertal). He found the full support of his parents and brothers and sisters, who were all anxious to contribute to the prosperity of the enterprise from the smallest beginning with hard work and iron diligence.

The machines necessary for the production of metal saw blades were initially constructed by the company itself in rented rooms. On July 5, 1903, the birthday of Mr. Ernst Graef jr., the first saw blades could be finished and put on sale.

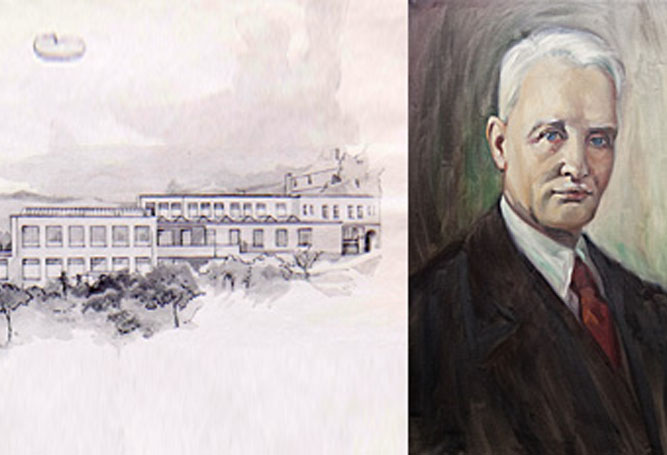

Soon relations with foreign countries were established, production expanded and in 1913 the means were available to build a factory on the company’s own land in Oberbergische Strasse.

The war 1914-18 made great demands on the company owners and employees, who endured these difficult times in loyalty and solidarity.

Following the untimely death of Mr. Ernst Graef Jr. in 1921 his siblings took over the company of the same name. In 1924 the factory was extended by an extension, divided up and continued under the names of the respective owners.

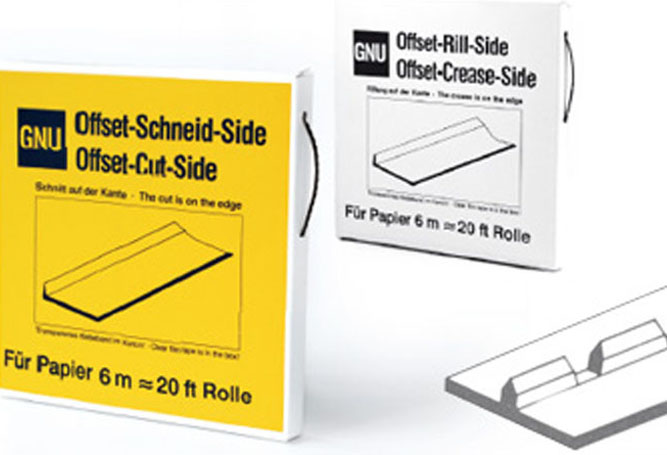

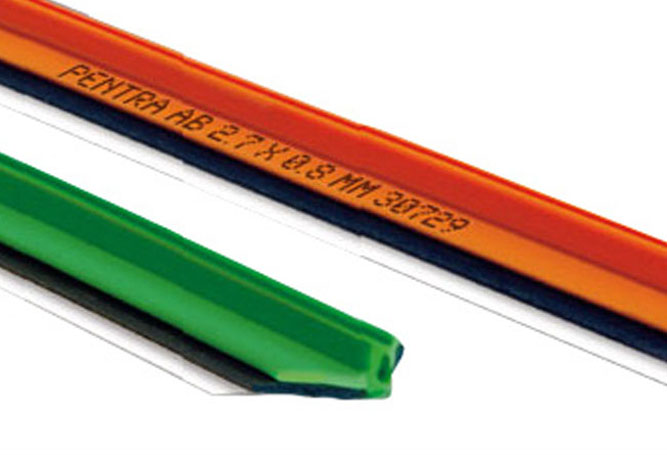

In the following years, Mr. August Graef, a long-time employee of his brother Ernst, always tried to keep up with the development of technology in his company and to be in good contact with his customers. Proven employees support him in his efforts to bring the “GNU” metal saws and metal band saws into the best reputation at home and abroad.

Adverse circumstances before and during the war of 1939-45 did not permit the expansion of operations, but the factory was spared war damage. It was not until 1950-51 that the long-planned extension could be built. Modern machines and high-quality testing equipment are available to our experienced specialists and guarantee first-class quality products.

The experience and performance of the past 121 years will be our obligation to maintain the good reputation of our products in the future and to justify the trust placed in us.

(from 50 years GNU, Dr. Emmi Koll 1953, edited)